Movable pulsating vacuum steam sterilizer

Medical pulsating vacuum steam sterilizer for rapid deployment, operation and high load operation

SCM series 180 litre single pulse vacuum sterilizer is a kind of efficient and environmentally friendly sterilization equipment. The equipment is easy to operate, quick to operate, convenient to maintain and beautiful in appearance. In the medical institutions of different functional units quickly between mobile and re deployment of professional design to meet the emergency use of a variety of operation room, central supply room, fast arc is also very suitable for outpatient treatment room, plastic surgery, dental clinic and other large and medium sized medical institutions were required. The product is programmed with a range of sterilization procedures that can be used to meet the needs of a wide range of medical devices. On the basis of rapid and convenient, the strict requirement of sterilization result is maintained, and the highest level of sterilization guarantee can be obtained.

No installation, convenient use and maintenance

The medical center, laboratory, operation room and small clinics face sterilization growing demand, more and more types of equipment, the urgent need of a flexible, convenient and widely used in high performance of sterilizer. SCM series 180 litre single pulse vacuum sterilizer is designed to meet this demand:

• in unit time and unit space, the sterilization efficiency is efficient and quick.

• 180L's inner chamber volume can easily meet all the sterilization facilities needed for any major operation and ensure rapid start-up, warm-up and operation.

• minimum requirements for external use: small footprint, no plumbing. No steam source is needed.

• set up double safety door lock.

• comes with casters to ensure that the equipment can be moved and fixed at will.

• one button opening and a variety of running procedures, so that sterilization work is easy and fast.

• the equipment needs no installation and low running cost.

• optimize the device width design to ensure that the equipment can be easily passed through each room.

• saves space and works in the smallest room.

• the inner chamber and the door of the sterilizer are made of 304 stainless steel. All the inside surfaces are polished and no impurities or spots are found.

Performance characteristics:

A: quick operation

No installation required

1: equipment comes with casters, handling, location, easy and convenient.

2: no external water pipe, steam pipe, no ground advance buried drainage device

3: only need to access a power cord, you can start immediately, "plug and play"".

4: the whole work trip 25-30 minutes.

Built in large capacity water ring vacuum pump

1: you can quickly extract the air in the sterilization room

2: the moisture in the sterilizing and sterilizing room can be quickly extracted so that the sterilized sterile articles can be quickly dried

Built in steam generator

1: can ensure that adequate steam can be provided to facilitate stable and fast operation of equipment

2: can be used continuously, a number of sterilization cycle, no waiting

Built in water tank circulation device:

1: you can save a lot of water. The equipment operates at full capacity and consumes only 5 litres of water a day.

2: through the water cycle and efficient heat exchanger, you can save energy consumption, and increase the speed of equipment.

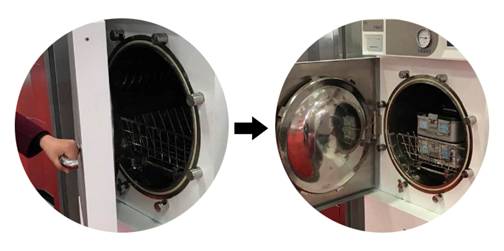

Two: easy to open the cavity door

The door of the chamber by rotating equipment incisors meshing patented technology. Easy to open and close, simple to anyone can operate this device.

Three: convenient way of fetching

Using sliding type inner car, gently pushing and pulling, loading and unloading of sterilized substances that can enter and exit the sterilization room, you can quickly and easily put or remove sterilized items.

Four: safe and reliable

1: the use of mechanical and electronic safety interlock device to ensure that the pressure in the sterilization room, the cavity door can not be accidental or error open.

2: door closed switch can avoid the cavity door is not completely closed in case of sterilization procedures start.

3: control system as long as the detection of the temperature of the cavity or the pressure exceeds the set safety value, it will send a signal to prevent the cavity door is opened.

Five: control systems and sterilization procedures

Control system

Microcomputer and color touch screen control system are adopted. Configure micro printer. Set parameters, view data, one click operation. The built-in memory can store at least 200 sterilization program history records, and the USB interface can be inserted into the USB storage device, and the previously sterilized data can be transferred to an external memory. Easy to view and print.

Sterilization procedure

There are 8 sets of sterilization procedures, including fabric program, instrument program, liquid program, custom program, custom program two, B-D test program, drying program and preheating program 2 sets of test procedures (leak test procedures and PCD test procedures) and several custom sterilized procedures can cover 100% of all sterilization requirements.

|